KOMES is a rapidly growing company in which the main business area is specialized engineering services.

Our main aim and objective is to take up and solve challenging, untypical projects.

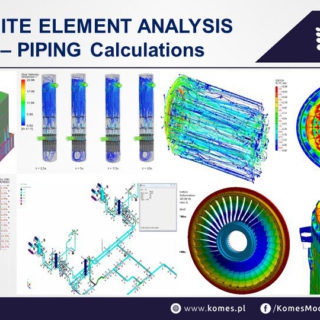

We carry out commercial simulation analysis based mainly on the finite element method (FEM) at the expert level.

Verified is security and functionality of the clients solutions.

In addition, the measurements, Diagnostics and tests of prototype and existing structures are carried out. There are prepared expert opinions, reviews and recommendations on issues in the theory of the structure, dynamics, mechanics of interaction of vehicles and equipment, non-conventional solutions.

KOMES SP. z o.o. is a modern engineering company founded in 2011. Core of the our group are young, highly skilled engineers with very high potential.

Laboratory and technical facilities are continually developing. The company has the Mobile Laboratory of Mechanical Measurements.

NUMERICAL ANALYSIS

Calculations are done in such way that the project meets the requirements of recognized standards and best engineering practices.

Calculation MES

-Linear and nonlinear static and dynamic analysis

-Fatigue and crack propagation analysis

-Impact loads (crash test) analysis

-Kinematic – structural analysis

-Thermal – structural analysis

-FSI (Fluid-Structure Interaction) analysis

-Modal analysis

-Transient analysis

Calculation CFD

-Flows in rotating equipment: pumps, compressors

-Internal flows: valves, regulators

-External flows: liquids and gases, steady-state or transient flows

-Multiphase flows: evaporation, condensation, smoke propagation

-Heat exchange and heat transfer

-Fluid mixing issues

-Turbulent flows

-Combustion processes

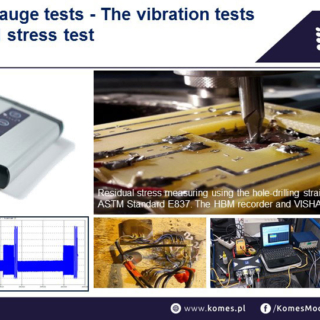

TESTS AND MEASUREMENTS

We carried out measurements and tests of prototype and already in use designs.

We verify:

-Farmes and carbodies, semi-trailers, trailers

-Load-carrying machine subassemblies

-Cranes, hoists and overhead cranes structures

-Responsible structure components

-Pressure vessels structures

-Steel load-carrying structures

-Pipelines

Special tests:

-Residual stress measurements by the hole drilling method

-Gear stress tests

-Large deformations studies

-Testing in hazardous environmental conditions in explosive zone (EX)

-Hot deformation studies of parts at up to 950 ° C

-Monitoring progressive cracking

-Wireless measurements on rotating parts

-Strain gauge measurements

EXPERTISES AND COUNCELLING

Comprehensive technical advice at every stage.

Technical expert assessments

-Technical condition evaluation of structures, machines and pressure equipment

-Assessment of technological and design advancement

-Wear and tear assessment of machinery and equipment

-Elaboration of measures for reconstruction or modernization of machinery and technological equipment

Material testing:

-Materials science of metallic alloys

-Welding metallurgy, particularly nickel, iron and aluminum alloys

-Material selection and machine manufacturing technology selection

-Corrosion diagnosis

-Quality tests of welded joints

-Control of machines operating temperature

THE SALE OF SOFTWARE AND THE IMPLEMENTATION

A stable place in the company’s activity is the sale of engineering software and technical support services for all offered products

-MIDAS NFX – a tool for providing advanced and efficient structural simulations, as well as flow simulations and optimization

-TECPLOT 360, CHORUS – Advanced software for data and results post-processing.

-AFT – a tool allowing dynamic calculations of liquids and gases flow in pipelines. Allows for fast, intelligent selection of sizes and types of pipelines, and the whole installation.

ACTIVITIES IN THE SPACE SECTOR:

TD 15-Tribology and mechanisms

TD 20 – structures and pyrotechnics

TD 21-Thermals

TD 24-materials processing and treatment

TD 25 – quality, reliability and safety

TECHNICAL DIAGNOSTICS FACILITIES:

We use a variety of available technologies, engineering software and measurement devices and their selection is determined by the specification of the tasks.

We have the following Software:

- CAD: Draftsight, SolidWorks, ZW3D, SpaceClaim

- FEM: Ansys, Code-Aster, CosmosM, Femap, NastranNX, Robot, VVD, MIDAS NFX

- CFD: ADINA, ELMER, OpenFoam, Paraview, Tecplot 360

- PIPING: AutoPipe, Bentley PULS, Caesar II, Pipenet, Pulsim, Triflex, PV Elite, AFT

For measurements moden brand equipment is used as well as own designed measuring equipment which allows to work in explosive zone (albo environment with explosive atmosphere), defined according to ATEX European directive.

We also offer mobile service Mechanical Measurements for quick Diagnostics equipment and installation at the place of use, which reduces costs associated with potential downtime and improves internal Maintenance Departments.

Recived results are processed and handled in real time which gives the possibility of immediate visualization and evaluation.

For Our Clients primarily development and improvement of their companies is important. They appreciate quality, safety, innovation and experience. We use our maximum knowledge and skills to meet the expectations of any Client. We work with many companies both Polish and foreign. Among them are small but having a huge potential economic entities, private entrepreneurs, multinational corporations, tech companies and academic institutions working in virtually every branch of industry.Projects that we carry out are based on trust and long-term strategic cooperation. We know that the plans and concepts entrusted to us are extremely valuable.

Due to the existing agreements (NDA) the list of our customers is confidential. For that reason references are available for inspection only upon request. We have been realized about 350 projects.